CNC Six-Sided Drilling Machine C6

Advantages:

CNC Six-Sided Drilling Machine belongs to other general equipment manufacturing industry in the construction machinery manufacturing industry. Firstly, raw materials such as steel, square tube and aluminum are processed by opening, welding, machining and painting, and then finally assembled with other accessories into CNC six-sided drill.

CNC Six-Sided Drilling Machine belongs to other general equipment manufacturing industry in the construction machinery manufacturing industry. Multi side drilling machine, so called six-sided drilling machine, is perfect to grant drilling on 5 or 6 sides of the panel, grooving and routing operations.

CNC Six-Sided Drilling Machine Functions

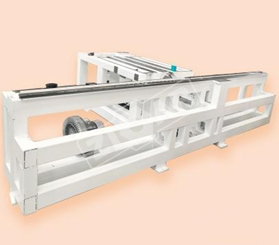

- Steel rack structure with one-piece framework.

- One time Completing the workpiece drilled in six sides, and front or back grooved.

- Multi-shift production and easy operation, production efficiency up to 1.3-1.8 slices/min. and 8 Hourly capacities up to 190 sqm. (Unfolded area) – 230 sqm. (Unfolded area).

- Minimum board support for single machine 35mm*70mm.

- Loading table and discharge table are covered with air floatation hole, that could protect the workpiece from damage effectively.

- Long guide rail for Y-axis guarantees maximum machining efficiency. Double grippers and automatic side leaning device guarantee the stability of the workpiece during the movement.

CNC Six-Sided Drilling Machine Product Features

|  |

|

|

|  |

|

|

CNC Six-Sided Drilling Machine Product parameter

| C6 Basic Information | |||

| Processing Range | Processing Plate Size Range: | Length | 70mm-2750mm |

| Width | 35mm-1200mm | ||

| Thickness | 12-50mm | ||

| Processing Type | Machining Hole Type | Depends on the Tool | |

| Door Reaming Processing Method | Add Drilling Package | ||

| Shaped Plate Parts (Can be Processed or Not) | YES | ||

| Six-Sided Drill Grip (Fixed or Not) | Intelligent Three-Stage Lift Function | ||

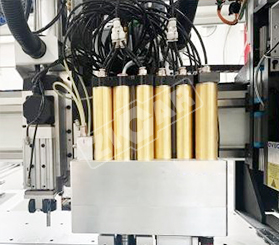

| Equipment Configuration | Drill Package Parameters | Number Of Drill Packs | Upper *1 & Lower*1 |

| Number Of Upper Drill Pack Bits | 12 Vertical Drills, 8 Horizontal Drills, 12 Auxiliary Cylinders | ||

| Number of Lower Drill Pack Bits | 6vertical Drills, 12 Auxiliary Cylinders | ||

| Number of Drill Package Auxiliary Pressure Plate | Drill Package Integrated with 12 Built-In | ||

| Number of Lower Spindles | 3.5kw Spindle *1 | ||

| Basic Parameters | Program Docking | Mpr/Xml/Dxf/Ban | |

| Usage Mode | Alone Or Inline | ||

| Scanning Method | Two-dimensional Code Scanning (Standard with Handheld Scanner) | ||

| Total Power | Around 26kw | ||

| Working Pressure | 0.8mpa/M2 | ||

| Net Weight | Around 3800kg | ||

| X Axis | 130m/Min | ||

| Travel & Maximum Positioning Speed of Each Axis | Y Axis | 80m/Min | |

| Z Axis | 50m/Min | ||

| U Axis | 130m/Min | ||

| V Axis | 80m/Min | ||

| W Axis | 50m/Min | ||

| A Axis | 80m/Min | ||

| Length | 4300mm | ||

| Equipment Size | Width | 2800mm | |

| High | 2200mm | ||

| Guide Rail | German Roust World | ||

| Accessories And Brand

| Important Components | Slider | German Roust World |

| Ball Screws | Taiwan TOCO | ||

| Rack And Pinion | Taiwan TWIN | ||

| Servo | LEADSHINE | ||

| Drill Package | YOEVO | ||

| Spindle | ZHENGDA/SKMOTOR | ||

| Gripper Structure | Customized (Intelligent three-stage lifting gripper) | ||

| Reduction Gears | TAIBANG/ SHIMPO | ||

| System | Control System | LNC/NC STUDIO | |

| Optimization System | SANVEGA (Optimal algorithm for punching, lift 5mm higher for processing) | ||

| Framework | Body Structure | One-piece Structure | |

| Frame Process | Annealed to eliminate stress | ||

| Electrical Components | Drag Chain Cable | ANYANG/RICHE/JIUKAI | |

| Solenoid Valve*2 | EMC /AIRTAC | ||

| Pneumatic Cylinder*2 | EMC /AIRTAC | ||

| Circuit Breaker | CHINT | ||

| Inverter | E&T | ||

| AC Contactor | SCHNEIDER | ||

| Thermal Relay | CHINT | ||

| Intermediate Relay | JAPAN OMRON | ||

| Switching Power Supply | MEANWELL | ||

| Photoelectric Switch | TAIWAN FOTEK | ||

| Fiber Optic Sensor | JAPAN PANASONIC | ||

Main Production Equipment

| Equipment Name | Equipment Brand | Number |

| High Precision Automatic Five-Sided Gantry Machining Center | TAIWAN AWEA | 5 |

| High-Precision Vertical CNC Machining Center | CARLOS | 6 |

| Welding Robot | JAPAN OTC | 8 |

| Laser Fiber Optic Metal Cutting Machine | BAISHENG | 2 |

| Laser Interferometer | ENGLAND RENISHAW | 2 |

| Ball barometer | ENGLAND RENISHAW | 2 |

| Vibration Ageing Machine | SHENHUA | 2 |

| Bending Machine | 4 | |

| Sawing Machine, Milling Machine, Punching Machine, etc. |

Links: CNC Side Drilling Machine CK1526x1 CNC Drilling machine CK1526 Horizontal Drilling Machine C7

Related products

FAQ