by zicar-ad

Share

The difference between using a six-sided drill and a CNC Side Drilling Machine

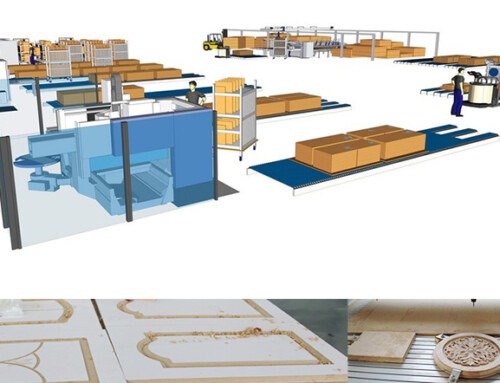

Compare Factory efficiency (Daily output (8 hours) ):

CNC Side Drilling Machine + CNC Side Drilling Machine = 50 boards

CNC Cutting Machine CR4 +CNC Six-Sided Drilling Machine = 100-120 boards

CNC cutting machines are used in the past to punch holes, slot and cut boards. However, this process requires a time consuming turning process on both the front and back of the board. Thankfully, with advances in technology, this step can now be omitted, resulting in reduced time requirements for the same result.

- CNC Side Drilling Machines are essential in order to drill multiple sides of a plate quickly and efficiently. This type of machine drastically reduces the time otherwise spent drilling each side individually, making it an incredibly useful tool for any business that relies on producing multiple plates or other objects with multiple holes.

- The CNC Six-Sided Drilling Machine is a cutting machine that is replacing the need for front and back drilling, slotting and side drilling machines. This machine drills directly into the fronts and backs of multiple surfaces, streamlining the process and saving time. In addition, it also eliminates the need for a separate side drilling machine.

STAY IN THE LOOP