by zicar-ad

Share

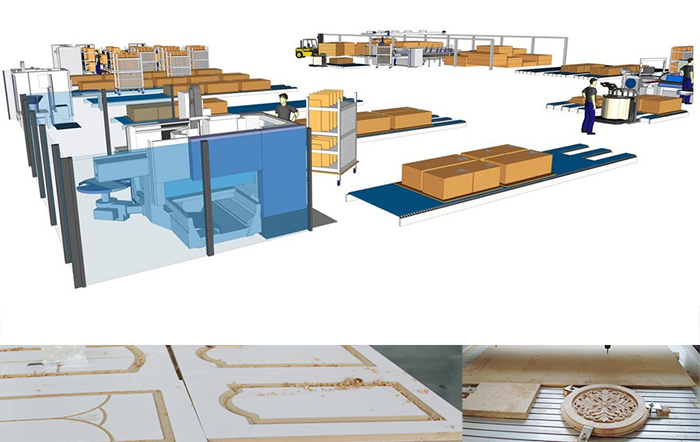

The Ultimate Guide To Choosing a CNC For Furniture Manufacturing

1.Research the Project Requirements

Before selecting a CNC machine, it is important to research the project requirements in order to ensure that the machine and software are an ideal match for your needs. Consider the design, materials, size of the product, production numbers, and other project-specific details when evaluating which type of CNC machines and software would best meet your requirements.

2.Identify Functionality Needs

When looking at CNC machines for panel furniture production, there are several functional options available. Consider whether you need drilling capabilities, cutting or engraving capability, punching capability for custom holes in materials such as wood or foam core board or if you need routing capabilities for 3D shapes from multiple cut areas. Each of these operations requires different types of machines so make sure to identify what type of functionality you need before continuing with the selection process.

3.Narrow Down Models by Specifications

Once you have identified the type of machinery based on project requirements and function needed then it is time to narrow down models by specifications such as size and power source; air/water-cooled motors; cutting speed; repeatability—both linear axes and rotary (because some project require a significant amount of part rotation); spindle speeds—or RPMs (RPMs affect how quickly material can be machined); work area sizes—which are generally defined by X-Y-Z coordinates; table style— vacuum tables allow parts to be secured while cutting from high speeds.; Feed Rates —the speed at which the material moves under the cutter; accelerations —the rate that drives can reach their maximum speeds; number of axes — most CNC routers moving gantries only have three; spindle torque rating — this impacts how much power it takes to cut through material.; classifications — Closed Loop Vs Open Loop system will provide reliable information regarding position control etc .

4.Analyse Company Support

The company’s reputation should also be taken into account when choosing a CNC for panel furniture production as their reputation will reflect how well they provide customer service including technical support possibilities as well as other after sales services like maintenance and operator training includes understanding latest advancements in technology Newer shops may want parameter configurations specific to particular industries like panel furniture which allows them easier operation ensuring optimal final results with very minimal effort. It is therefore important to evaluate service aspects before making any commitments with a supplier or manufacturer.

5.Evaluate Budget Limits & Set Up Costs

Money matters! Of course when determining price range it should not be more than what budget allows however cost should not determine quality either – analyse benefits you get depending on costs associated with various options prior making decision – this includes delivery , installation ,machine rigging ,time required for set up Also look at post-purchase servicing including help desk/tech support – this factor can make difference in performance between two potential top choices . Lastly evaluate all financial commitments that might incur during future updates if any .

6.Field Test Drive & Training Programs

Prior finalizing choice its essential run tests drive on respective model to identify short falls such product firmness , operator interface ease of use etc . Also consider company providing end user training programs include offering latest technological advancements that are crucial in order optimize product performance & quality consistently over time . Further assess whether these programs include emergency recovery clauses addressing service cases beyond supplier margin etc .

7.Maintenance Requirements & Warranties

Prior committing look into offered warranties including parts , labor warranties – Do know about preventive maintenance measures necessary ensure uninterrupted operating It advisable seek additional extended warranties also – but must clear understand what each portion covers !

STAY IN THE LOOP